Aluminum section for steel works

Inclusion Behavior during deoxidation alloying of ultra-low carbon IF steel . High temperature resistance furnace was used to simulate the actual production process of aluminum deoxidation and titanium alloy. The conversion of inclusions during this process was studied in detail by intensive sampling. It is found that the inclusions in steel are mainly spherical FeOx before aluminum is added. After the addition of aluminum, light gray spherical Al2O3 is formed first, and then transformed into ellipsoid or monolithic block Al2O3, and then rapidly aggregated into irregular Al2O3, and finally aggregated into Al2O3 clusters. The whole process is completed within 2 min after the addition of aluminum. After adding titanium, three kinds of Al-Ti composite inclusions were formed in the molten steel, but after adding titanium for about 4 min, they changed into stable Al2O3 phase. During the whole process of deoxidation alloying, the oxygen content and inclusions decreased, and the cleanness of the molten steel increased gradually.

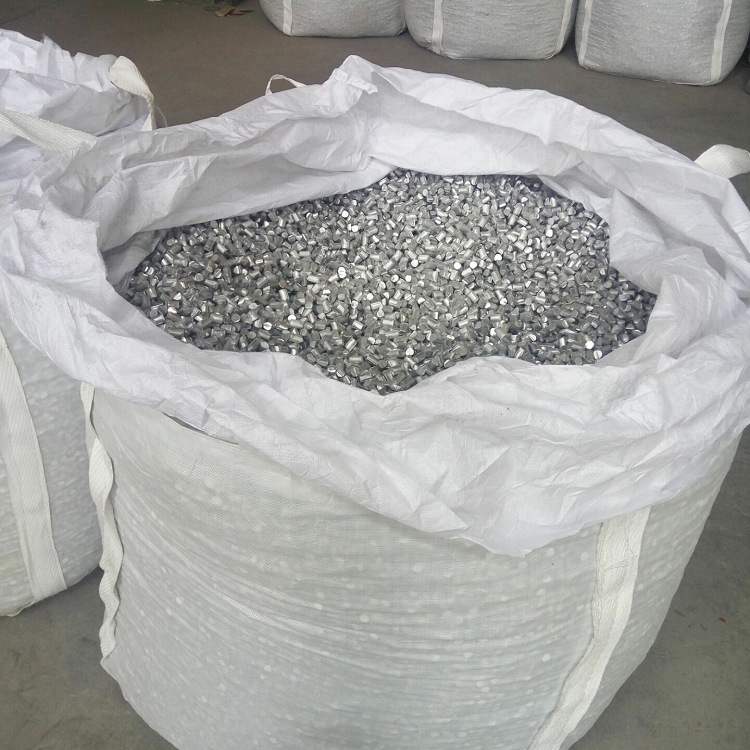

It is necessary to improve the process of adding aluminum to steel to enlarge the production scale of sedated steel with specified aluminum content. The current ladle aluminization process (in the process of converter and open-hearth steel production, the aluminization block weighs 14 ~ 16 kg), the average yield of molten aluminum is 20%, fluctuating widely between the upper and lower furnaces (actually from 0 to 30%). The yield of aluminum added to molten steel is low and unstable due to the mixing of aluminum with slag and atmosphere under the action of oxygen in it.

Core technology is an off-furnace refining method developed on the basis of jet metallurgy in the 1980s. The core is suitable for steelmaking and casting. What's the use of cored wire? Cored wire is a variety of additives added to molten steel or molten iron (deoxidizer, desulfurizer, modifier, alloy, etc.) crushed into a certain size, and then cold rolled low carbon steel strip. Include it as a composite material of any length. What is cored wire? Stainless steel alloy core-feeding machine refining machine.

The raw ore of deoxidizer component prepared by the preparation method of deoxidizer used in steelmaking is added with reducing agent carbon according to the component ratio of the prepared deoxidizer, and then crushed. The crushed material is continuously added with horizontal reflector furnace as fuel and heavy oil as fuel. , from the nozzle to the furnace injection fuel and air or oxygen-rich oxygen, heating the furnace charge to reach the temperature of 1300-1450C, continuous release of liquid product deoxidizer from the furnace, the residence time of adding raw materials in the furnace is 25-100 minutes.