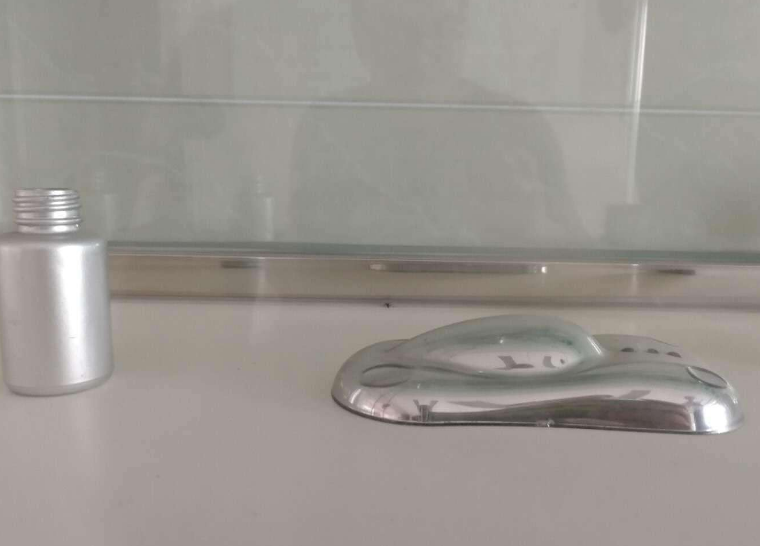

Aluminum silver paste for printing ink

The special aluminum pigment powder for ink is solvent-free, convenient to use, and has a long storage period. It can be reduced to aluminum-silver paste after solvent soaking. Offset and screen printing, paint. Green and environmental protection is still the theme of today's society. The development of pure water-based environmentally friendly inks is a development trend. It has the characteristics of zero VOC emissions, no irritating odor, non-flammable, and green and healthy. In recent years, it has been in the green packaging and printing industry. Universal application. With the development of society, people's pursuit of exquisite packaging of goods has greatly increased. The gravure printing has the characteristics of thick ink layer and rich layers, and the prints obtained are high-end and exquisite, which can satisfy people's pursuit. Silver ink is also widely used in the exquisite packaging of various commodities with its special color and metallic luster, and is favored by people. Therefore, the research and development of pure water silver gravure ink is an inevitable trend, it is a new type of green printing consumables with great development prospects and market potential. In this paper, the preparation and optimization of water-based silver gravure inks have been researched. The influence of the type of aluminum powder pigment, the ratio of pigment to base, the type and amount of dispersant, the stirring speed and time on the dispersion performance of the base ink were explored. The effects of the type of film-forming resin and the ratio of film-forming resin on the printing performance of ink particle size, gloss, surface tension, and leveling were explored. In addition, this paper improves the instability of pure water-based aluminum powder ink through degreasing treatment and sol/gel modification experiments on aluminum powder pigments. The effects of ethanol solutions with different concentrations of phosphoric acid on the degreasing effect of aluminum powder pigments were explored; the effects of aluminum-silicon ratio, water-silicon ratio, catalyst dosage, volume volume, and reaction time on aluminum powder pigment modification coating experiments were explored.

Because aluminum powder has the defect of poor corrosion resistance, the silver paste ink formulated by it is not stable, and problems will occur during storage and use, and its color is single, which cannot fully meet the current needs of printing production. So in this paper, the surface coating modification of aluminum powder and the surface coloring of aluminum powder are used to improve this problem. The main research results have the following four aspects:

(1) First, using TEOS as the precursor, the SiO2 coated aluminum powder is prepared by the sol/gel method, and the optimal experiment is selected by analyzing the properties of the products prepared under each optimized condition system. The modified aluminum powder prepared in this system has good alkali resistance. Afterwards, the products were characterized by means of scanning electron microscopy (SEM), X-ray energy spectrometer (EDS) and infrared spectroscopy (FTIR). The gloss test found that the gloss of the product was low.

(2) In order to improve the glossiness of SiO2 coated aluminum powder, on the basis of single-layer inorganic coating, a precursor vinyl triethoxysilane (VTES) is added to perform inorganic/organic coating on the surface of the aluminum powder. Hybrid coating modification. After analyzing the product with SEM, FTIR, gloss test and acid and alkali resistance test, it is found that the acid and alkali resistance of the modified aluminum powder is very good, and the original metallic luster of the aluminum powder is well maintained.

(3) In order to prepare colored modified aluminum powder, while using the modified sol/gel method to hybridize the aluminum powder, the co-deposition method is used to deposit the phthalocyanine blue pigment on the surface of the aluminum powder, and then SEM, The product was characterized by FTIR, gloss test and acid and alkali resistance test, and finally a brightly colored blue inorganic/organic hybrid coated aluminum powder was obtained.

(4) Prepare the ink using the original aluminum powder and the three coated aluminum powders prepared earlier, investigate the performance of the formulated four inks, analyze their respective advantages and disadvantages and the reasons for their disadvantages, for the future improvement of aluminum powder silver paste ink And development provide a basis.

The modified aluminum powder developed through experiments has good corrosion resistance and maintains a good metallic luster. The silver paste ink formulated by it also has a certain application value, and lays the foundation for further research on silver paste ink in the future.